Engineering Module System

Engineering Module System(EMS):

- We are providing the engineering improving proposal, machine components and 2nd source parts for clean room application. (i.e.: equipment cover, hatching ….)

- WWTEK are located at Hsin-Chu near Science Park , Taichung and Guan-Zou ,China near Long-Hwa Industry park , to provide the fastest and efficient Engineering site survey & delivery service.

- EMS is basically on TFT-LCD, semiconductor precision equipment components manufacture and material better suggestion.

- WWTEK engineer group are having more than 10 year experience for clean room application , the highly qualified engineering work is the ensure for the precision & efficiency.

- Advanced Plastic & material are suggested to replace the high pollution & not endurable materials.

- For the machine parts, improving the durability and replace the not proper material is the major concern for EMS in clean room application.

- WWTEK can provide the on-site service for the measurement, sample evaluation & design engineering, if there is not available engineering source for the design work.

- Machine Bearings by customers design or ODM. (Order to make)

- The products delivery on time without failure during years.

- WWTEK is providing ESD: Anti-statistic Charge Plastic Plates (Transparency enhanced, anti-chemicals enhanced, physical performance enhanced) and provide machine work / cutting service for customers.

- WWTEK are providing. Anti-statistic Charge AL-Plastic Composite Plates, and provide machine work / cutting service for customers.

- Most famous BAYER made PC series (POLYCARBONATE).

1: For TFT-LCD wet etching equipments cover boxing and hatching (left: PC, right PVC-easy fragile & broken)

1: For TFT-LCD wet etching equipments cover boxing and hatching (left: PC, right PVC-easy fragile & broken) |

2: The mask carry box of TFT LCD -G3.5 generation of Litho- Module ,the original PVC for the problem of easy scratch , and improving to PMMA better in hardness and resistance to scratch

2: The mask carry box of TFT LCD -G3.5 generation of Litho- Module ,the original PVC for the problem of easy scratch , and improving to PMMA better in hardness and resistance to scratch |

3: TFT-LCD wet etcher PVC cover / hatching and change into better design in outer handle. So that the engineers might have good control for the maintenance and better handle when move them.

3: TFT-LCD wet etcher PVC cover / hatching and change into better design in outer handle. So that the engineers might have good control for the maintenance and better handle when move them. |

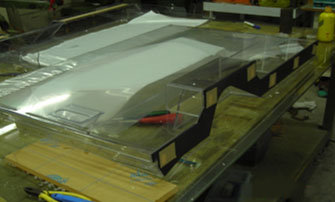

4: The cover for the CMP module of Semiconductor industry. This is quite complicate forming structure, and WWTEK complete all forming process in a single forming mode. and the water-prove is excellent than the several process with different mode.

4: The cover for the CMP module of Semiconductor industry. This is quite complicate forming structure, and WWTEK complete all forming process in a single forming mode. and the water-prove is excellent than the several process with different mode. |